Structural Fabrication Machinery 6th Edition

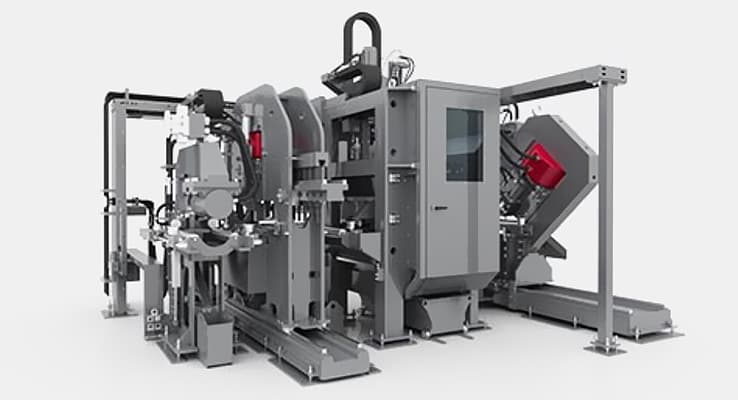

Gulf States Saw & Machine Company sells modular Fusion Arc welder cells, in-house courses, a large number of consumables and robotic welding parts. The instructors are both certified as welders and application engineers.